About QUICK

Intelligent soldering station

Intelligent soldering station

Desoldering rework station

Desoldering rework station

Smoke purification equipment

Smoke purification equipment

Electrostatic protection device

Electrostatic protection device

Testers

Testers

Dispensing device

Dispensing device

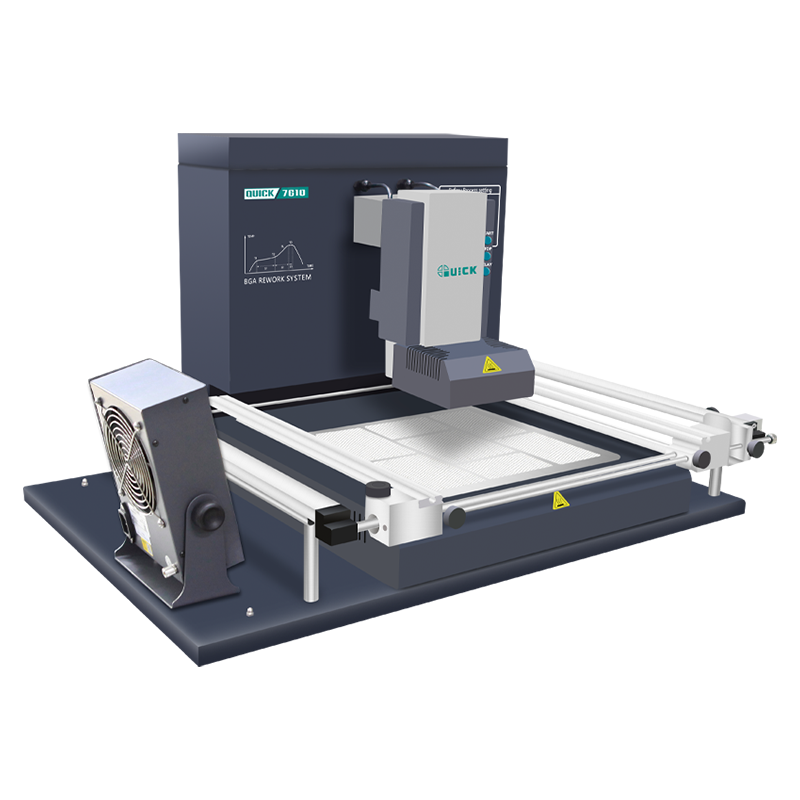

BGA rework equipment

BGA rework equipment

Summary

The QUICK7610 uses infrared sensor technology and is controlled by microprocessor. Infrared temperature sensors and infrared heating tubes are untouchable with precise de-soldering components. The soldering process is monitored by non-contact infrared sensors with good process control at any time. In order to control the soldering process and obtain non-destructive and reproducible PCB temperatures, the QUICK7610 provides 2400W heating power for all applications such as large, small PCB boards and lead-free soldering. Quick7610 uses cycle control reflow soldering technology to ensure precise, small process windows, uniform thermal distribution and a suitable peak temperature for high and reliable lead-free soldering.

Feature

1.No need of nozzles, no airflow in BGA ball process, high rate of success.

2.Top dark-infrared open type of heating, large area bottom infrared preheating, decrease the vertical temperature difference between BGA surface and soldering joints, shorten the rework time.

3.Use non-contact infrared temperature sensor, full-closed loop control of the temperature of BGA surface, ensure precise temperature process and even heat distribution.

4.The PCB fixture can be moved in four directions, easy installation.

5.IRSOFT interface with operating authority and profile analysis function.

| Model | QUICK 7610 |

| General power | 2400W(max) |

| Bottom preheating power | 1600W(infrared heating plate) |

| Top hot air heating power | 720W(红外发热管,波长约2~8μm) |

| Bottom radiation preheating size | 260*260mm |

| Max circuit board size | 420mm*400mm |

| BGA size | 2*2mm~60*60mm |

| 通讯 | 标准RS-232C (可与PC联机) |

| Infrared temperature sensor | 0~300℃ |

| Overall dimensions (L *W *H) | 800*580*520 (mm) |

| Weight | About 36 kg |