About QUICK

Intelligent terminal

Electric vehicle

Medical electronics

EMS industry

New energy

Aerospace science and industry

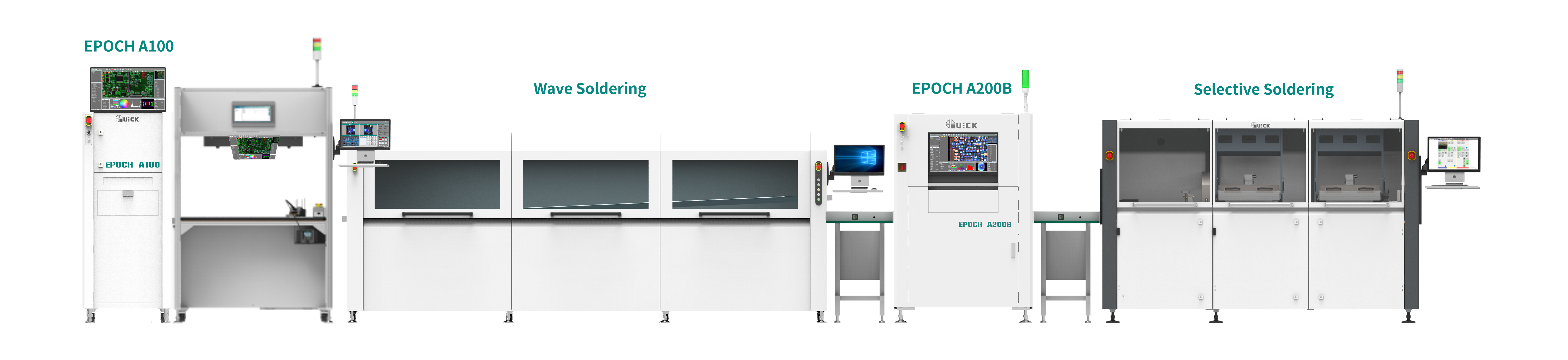

Zero defect solution to DIP automatic production line

One-stop solution

AOI in front of the wave soldering furnace performs the error and leakage detection of plug-in device, and AOI behind the furnace performs the solder joint and patch detection. The information such as the category and location of NG defects is transmitted to the selective wave soldering / soldering robot in the next station through the M2M data interaction information to automatically repair the soldering defects on the PCB and achieve the goal of zero defect of DIP automated production.

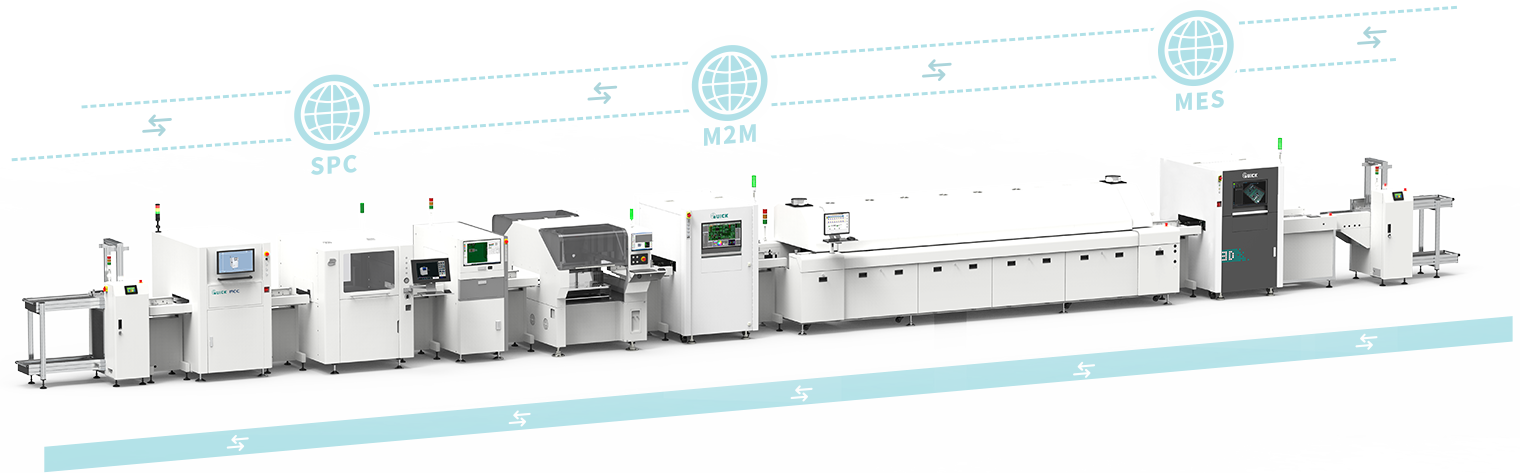

One stop solution for AOI detection of SMTproduction line

One-stop solution

The SMT production line is combined with SPI and AOI detection data before and after the furnace to carry out real-time analysis and closed-loop improvement of process technology, so as to realize lean production.

Solution to AOI detection of FPC high density, micro solder hole

One-stop solution

·t can detect the defects inside and outside the hole at the same time: solder connection, solder overflow, offset, empty soldering, cold soldering, less solder, foreign matters, etc;

·It can detect the scald, scratch, solder bead and other defects on the surface of components and FPC at the same time;

·With years of soldering process experience, the company has integrated in-depth learning algorithm to solve the detection problems of various types of weld joint defects, changeable positions and complex backgrounds, with zero missed judgment and high first pass yield.