About QUICK

Application area

Pin encapsulation & Conformal coating

Pin encapsulation & Conformal coating

Dispensing solder paste & Red glue

Solution to CCM / VCM precision dispensing

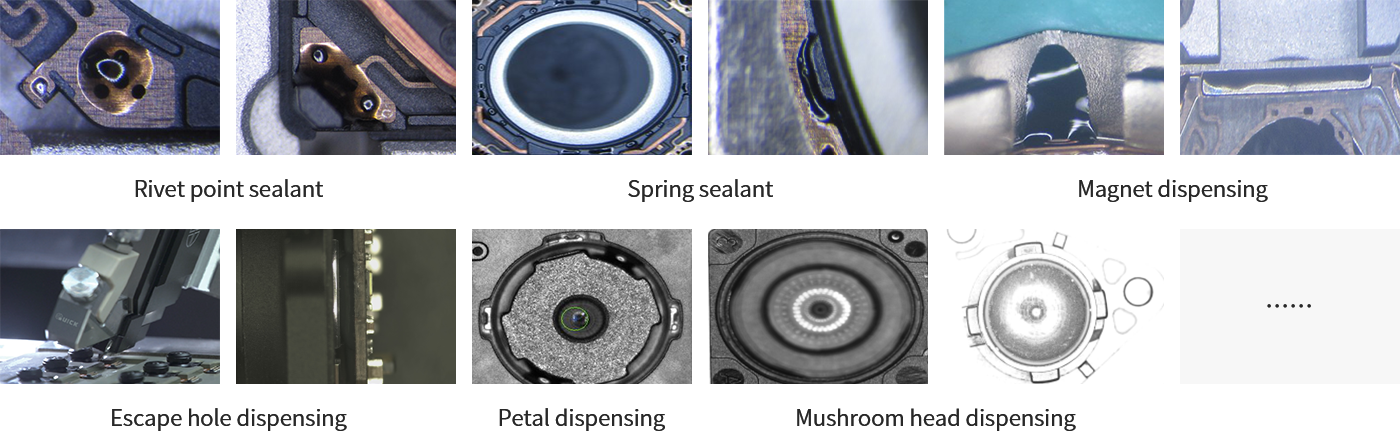

The boosting of industries including intelligent terminal, AR/VR intelligent wear, intelligent driving of electric vehicles, and intelligent home has led to a sharp increase in the demand of CCM/VCM. The dispensing process, such as neck glue, air hole dispensing, mushroom head dispensing, petal dispensing and FPC reinforcement, is widely used in the production process of CCM modules; Dispensing protection of VCM motor Pin solder joint; Application of double and three camera bracket gap dispensing and module dustproof and waterproof dispensing.

· Recheck the glue to eliminate batch defects

· Fully automatic magazine type automatic loading and unloading

· Contour recognition without Mark positioning

· Inclined dispensing to meet the needs of multi-angle applications

· Detection of feed plate status to avoid impact caused by product deformation

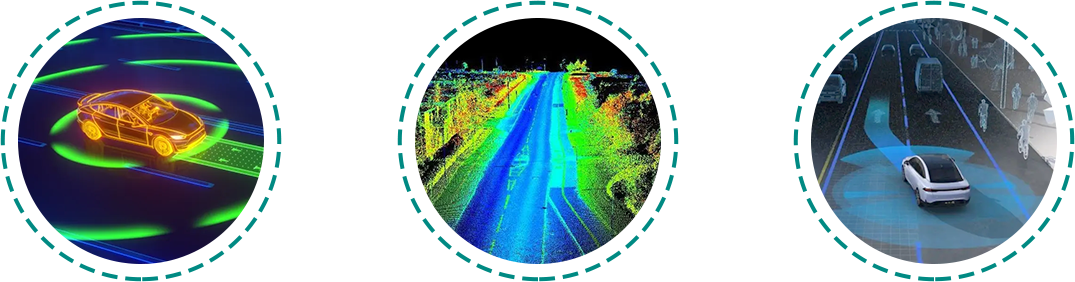

Solution to laser radar precise dispensing of intelligent driving ADAS

Industrial application of laser radar lens fixed dispensing:

· Dispensing UV glue for multiple lenses at different positions;

· High-quality dispensing allows no scattering or overflow;

· Dispensing requirements of different bench surfaces shall be taken into consideration due to the largely different product jigs. Laser height measurement shall be equipped to ensure the dispensing stability;

· Various kinds of products can meet the rapid and flexible line change production of multiple products;

· The equipment meets the level of class 100 clean environment.

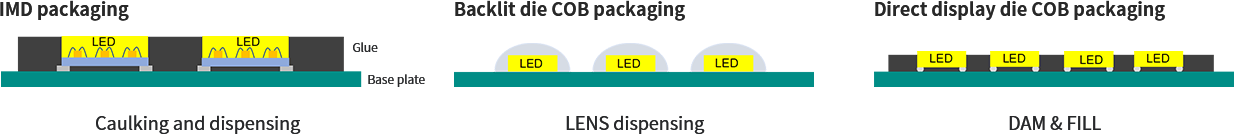

Solution to Mini-LED backlight precision dispensing

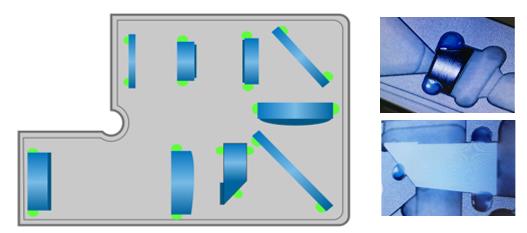

Solution to component encapsulation / reinforcement precision dispensing

| · mould proof, salt fog proof and moisture proof | · Reinforce components to give them certain anti-seismic capacity |

| · Reinforce the fillet weld leg / pins to make the fillet weld leg / pins more stable | · No glue is allowed at special positions, and the width of glue overflow shall be controlled within a certain range |

| · The components for the overall packaging process shall be completely wrapped by glue, and there shall be no empty position; | · The pins / fillet weld leg shall be used to encapsulate process components, and the pins / fillet weld leg shall be wrapped with glue. |

Solution to Underfill precision dispensing

· Sizing method: unilateral/L type/Utype;

· Glue weight control: glue weight line planning sizing;

· Clock control: repeat sizing at regular intervals;

· Rotary inclined sizing: meet the requirements of smaller overflow width.

Solution to SMT red glue & solder paste precision dispensing

| · The dispensing red glue process is mainly used to increase the adhesion of components, prevent the displacement and falling off of components in the process of furnace passing, and increase the firmness of large components. It is mainly applied in SMT patch and wave soldering process. · Dispensing solder paste is the previous process of soldering, which is mainly applied in solder paste spraying before SMT components and PCB soldering, FPC and FPC soldering, past-In-Hole plug-in soldering on FPC and FPC and through-hole PCB soldering processes that cannot print solder paste due to space constraints. · Glue quantity control, glue consistency and quality stability under high efficiency operation; · The equipment stability can meet the requirements of high-speed flight operations. |