About QUICK

Thermo-Compression Bonder

AI

High performance computing

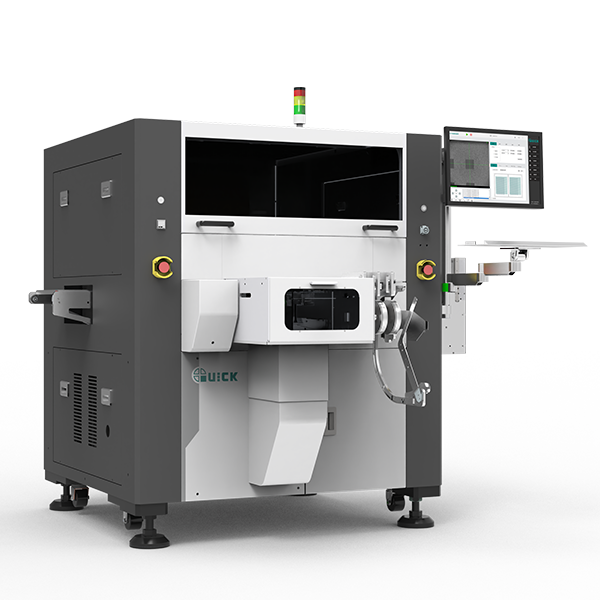

High Speed Die Bonder

Discrete device

Integrated circuit

MEMS, Transducer

Thermo-compression Die Bonder

Power semiconductor

New energy vehicle

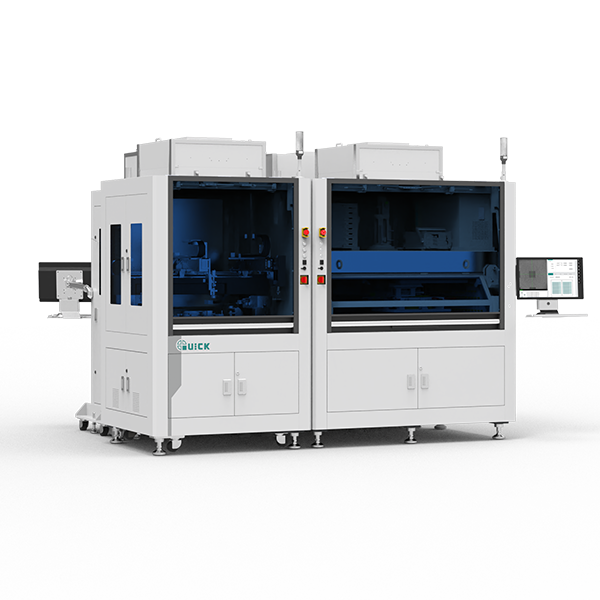

Multifunctional Die Bonder

Power semiconductor

New energy vehicle

Silver Sintering

Power semiconductor

New energy vehicle

Vacuum Oven

Power semiconductor

Automotive

Aerospace

Formic Acid Oven

Power Semiconductor

Automotive

Industrial

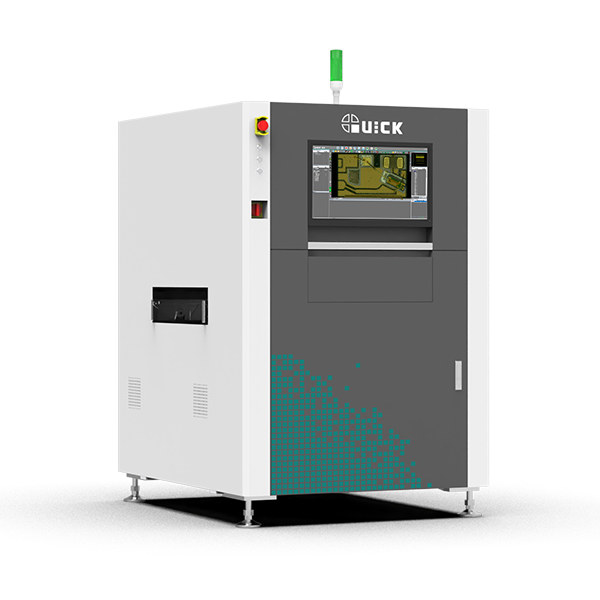

Die Packaging AOI

Photoelectric Component

Power Module

T/R Module

Die Packaging