About QUICK

Intelligent soldering station

Intelligent soldering station

Desoldering rework station

Desoldering rework station

Smoke purification equipment

Smoke purification equipment

Electrostatic protection device

Electrostatic protection device

Testers

Testers

Dispensing device

Dispensing device

BGA rework equipment

BGA rework equipment

TR1350 Intelligent Lead-free Rework Station

独立控温 定制风量

极速升温,热能充沛

休眠自动降温,会思考的散热系统

ESD接地监测,使用安全

Innovative process

Improve Desoldering Efficiency

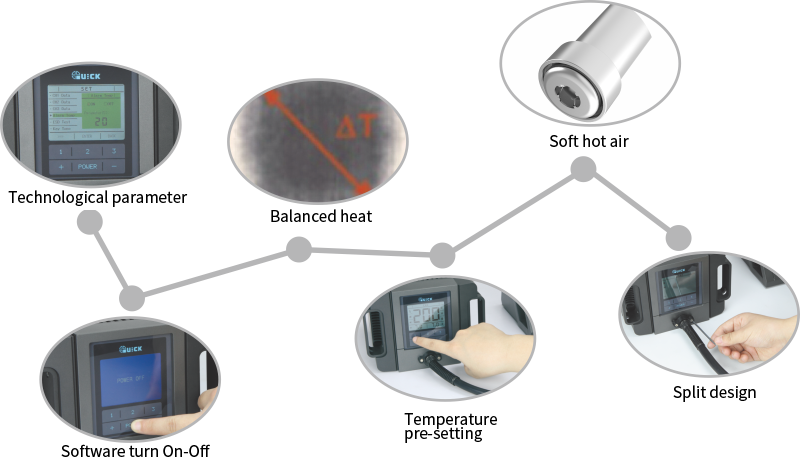

| Large power design, ensure sufficient heating, smart distribution, maximum power up to 1300W |  | Output constant airflow, unaffected by nozzle dimensions and nozzle tube deformation |

| Zone heating design, preheating and fast reworking combined together, realizing high efficiency and safety |  | Auto identification design, alarms if soldering iron does not match with soldering station |

| Password lock function, preventing production process parameters from being changed with permission |  | 3 different temperatures can be switched fast, meeting different soldering process |

| Safety design for sudden power reset to prevent automatic heating |  | Real-time monitoring of ESD grounding function, ensuring ESD safety of soldering products |

| Touch type sleep function |  | Both Celsius and Fahrenheit degrees are available |

| Machine On-Off via software, low standby power |  | Auto power off function, decreasing consumable parts cost, saving energy |

Intelligent efficient and safe reworking

With constant air flow, abundant heat and high efficiency,it is particularly suitable for special applications reworking, such as low-temperature, big components and high heat-consuming.

Quick nozzle replacement

Specifications

Model | TR1300 | TR1300A | TR1350 |

Power | 1300W | 1300W | 1300W |

Operating voltage | 110V/220V AC | 110V/220V AC | 110V/220V AC |

Temperature range | 100~500℃ | 100~500℃ | 100~500℃ |

Temperature stability | ±2°C(Still air without load) | ±2°C(Still air without load) | ±2°C(Still air without load) |

Air volume | 6-70L/Min | 6-70L/Min | 6-70L/Min |

Overall dimensions | 215*230*155(mm) | 215*230*155(mm) | 215*230*155(mm) |

Heating element | H618A | H618A | H618A |

Weight | About 5.3kg | About 5.0kg | About 5.3kg |

Split type hot air pen | √ | √ | √ |

Program fast switch | √ | √ | √ |

ESD grounding monitoring | √ | √ | √ |

Network communication | √ | - | √ |

Temperature automatic correction | - | - | √ |

Programmable temperature zone | - | - | √ |

Multi-section zone heating | - | - | √ |

Applications | • Suitable for reworking various components, such as SOIC, CHIP, QFP, SOP, PLCC, SOJ, BGA and QFN • Application: Heat shrinkage, drying, paint removal, defrostation, preheating, sterilizing, adhesive soldering etc. • Air volume adjustable, suitable for small and large air volume heating occasions. • Suitable for lead-free hot air reworking occasion. |  | |

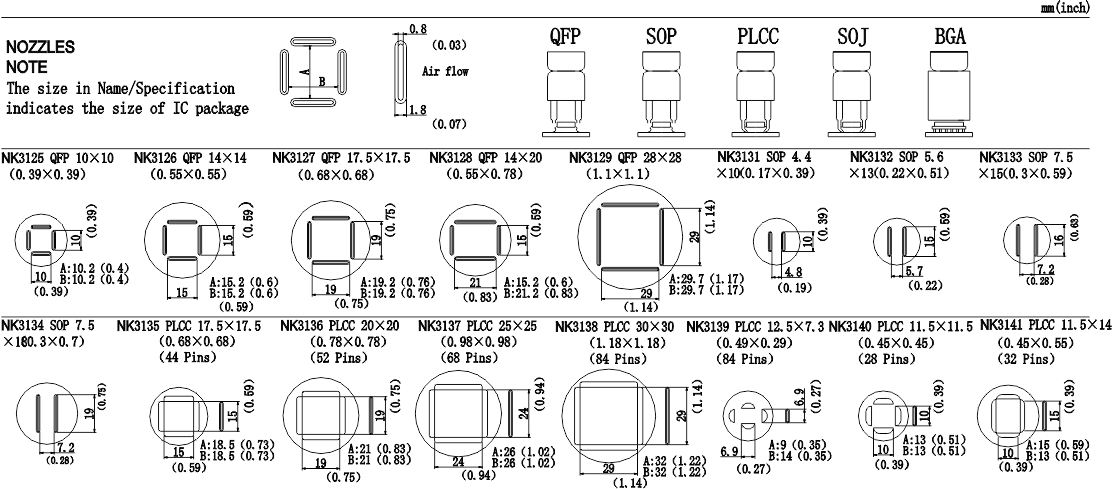

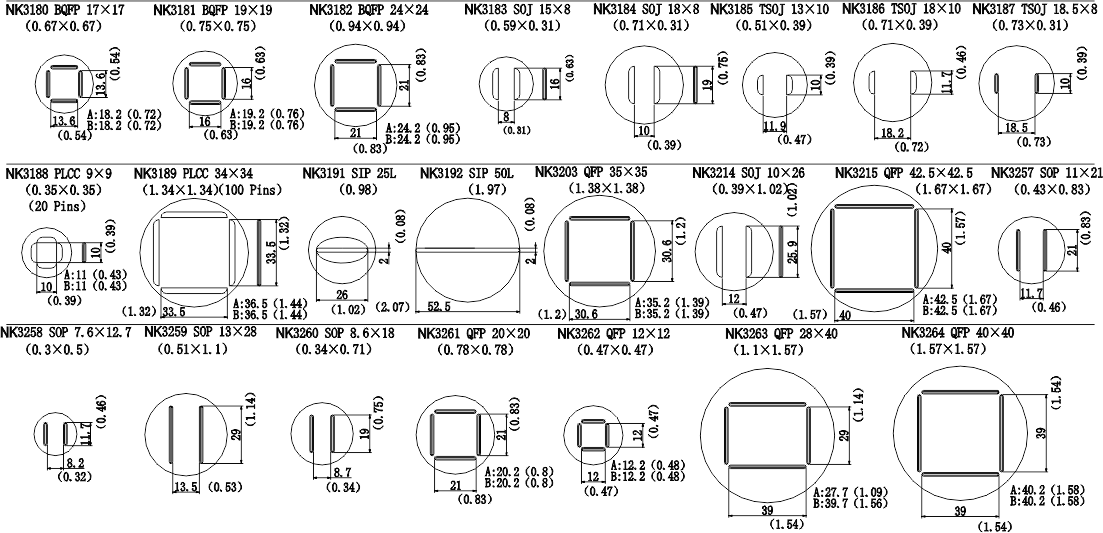

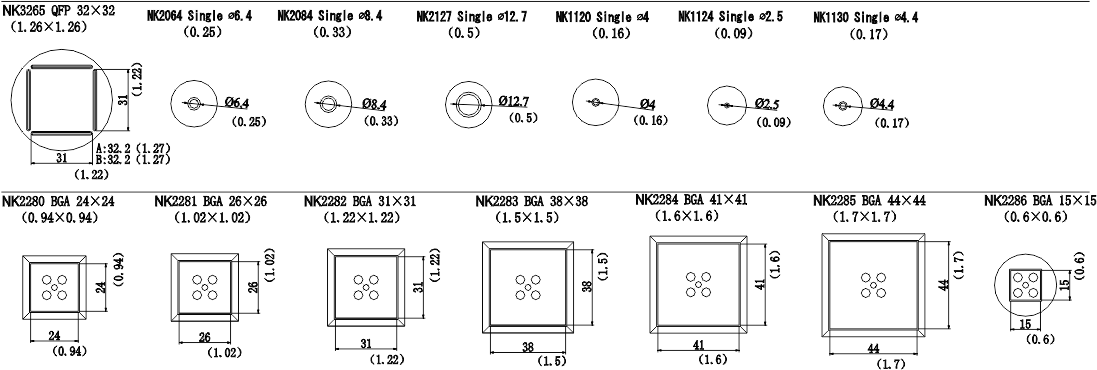

Nozzle